Capstone I: Progress Blog #2

- Kyle Le

- Feb 13, 2020

- 5 min read

Updated: Sep 9, 2020

Problem statement, project goals, and key concepts

Since the last blog, the problem statement has become more defined and refined. After extensive research and reaching out to external sources in the medical field, the problem at hand is developing a cost-effective prototype that will serve as an emergency respiratory during transport. Currently, portable ventilators are well developed and work very efficiently, however, the cost of equipment is too expensive to distribute to medical professionals at most hospitals. In order to meet the needs of the medical industry, emergency services, like ambulances, continue to use the manual BVM to administer oxygen to those in need. The issue is the fact that these BVM’s deliver an inconsistent flow of oxygen by manual compression in terms of tidal volume and pressure. The tidal volume represents the volume of air delivered per pump by a ventilator to the patient and is officially defined as the normal volume of air that is inhaled and exhaled by the lungs during breathing.

After doing research on the given issue, it has been concluded that several different types of medical professionals provide inconsistent results during manual compressions of a BVM. Furthermore, the pressure of air within the alveoli in the lungs after an exhalation, known as positive end expiratory pressure (PEEP), usually exceeds the recommended pressure per individual during emergency situations. PEEP is usually measured in comparison to atmospheric pressure or gauge pressure and is the standard that the industry uses to analyze respiratory needs. The alveoli are small spherical sacs in the lungs located at the end of the branch-like bronchi and bronchioles that are responsible for oxygen exchange.

Because of these inconsistencies during manual respiration, the prototype that will be engineered by our group is to supply compressions in a controlled and constant fashion, eliminating the fluctuations in tidal volume and PEEP.

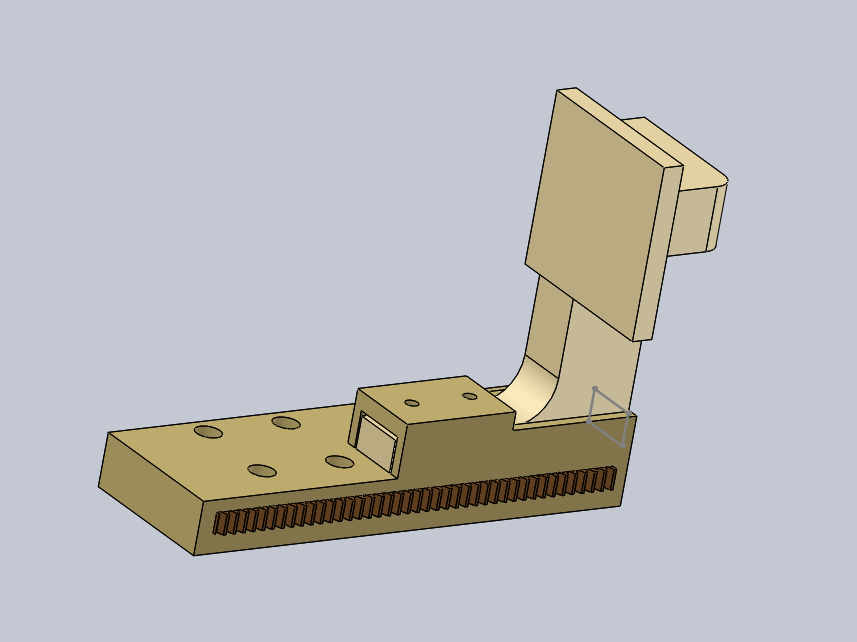

Therefore, the goals of the following project are to prototype, fabricate, and test a low-cost mechanical device that automates the compressions of a bag valve mask to provide the tidal volume, pressure of air, and breath frequency for the patient with the operation of only one person. First, we will perform background research on respiratory problems and current ventilation devices, and document results. Next, we will finalize the compression system and perform Finite Element Analysis on key components to choose the optimal design based on manufacturability and functionality. After that, we will research appropriate microcontrollers, batteries, and motors, and build a complete circuit system that can compress the bag with desirable torque, speed, and frequency. After assembling the mechanical system and electrical parts, we will develop and test the code of the microcontroller to refine the accuracy of the program.

Current state of background research into the problem and solutions

The current state of background research has progressed throughout the last blog. Where we stand now, the development of key medical insight has been provided by reaching out to an assistant nurse manager at St. Luke's hospital, confirming the need for an alternative, cost effect portable respirator. Statistics on the cost of portable ventilation are currently available to the group as well as the technology associated with these portable ventilation devices. Additionally, the problems associated with manual respirators such as the BVM have been identified as well as the inconsistencies of delivery of oxygen delivery in various types of individuals. Although data is available to the group specifying volumes of air during respiration, the rate of air delivery still needs to be identified for a range of individuals, by size, age, weight, etc.

With the price of current portable ventilation practices being too expensive for the industry to implement, the solution that the group has proposed is to prototype a cost-effective device using affordable components that can also prolong the usage of the device as well. Once a design has been finalized by the group, the fabrication and material selection will be under review to optimize these conditions to ensure an affordable product. The portability of the device is also a key factor during the design process. By maximizing the performance of the device under a range of design configurations, the group can choose the best form factor of the device under a range of working conditions. Lastly, the inconsistencies of manual ventilation will be addressed during the implementation of a mechanical compression system, that can be adjusted over a range of magnitudes in order to mediate the volume and pressure of air provided to the patient. The group has talked briefly about mediating the rotational speed of our mechanical system by designing a circuit that can alter the amount of voltage sent to a DC motor. The adjustment in speed can limit the force and or rate of compression of our air supply.

Key figures

Transmural pressure is the difference in pressure between the pleural cavity (the membrane that holds the entire lung apparatus) and PEEP. During inhalation, PEEP drops and transmural pressure rises above atmospheric pressure. During exhalation, PEEP rises and transmural pressure drops below atmospheric pressure.

Compliance: how easily the lung expands. High compliance = lung expands easily. Measured in mL/cm H2O). Compliance = change in volume/change in pressure of pleural cavity (cavity that houses the lungs).

These 2 figures give us useful insights into how the human lungs operate during ventilation. During testing, we will likely use a CPR dummy or rubber balloon for obvious reasons, as shown in Figure 1.7. Since we will test the prototype in a controlled environment, it is helpful to understand how a rubber balloon can simulate the lungs and how it can affect testing methods and results. To understand the problem better, we have also looked at the pressure vs. time profile during constant-flow mechanical ventilation. Understanding how airways resistance works can help us come up with a design that provides safe and reliable air pressure for the patients.

Projects goals

The goal is to prototype, fabricate, and test a low-cost mechanical device that compresses a bag valve mask in a programmed, consistent, and steady motion to provide the tidal volume, pressure of air, and breath frequency for the patient with the operation of only one person.

These goals are based on the research we have done on standards for BVM’s which includes providing tidal volume ranging from 300-840mL, breath frequency from 12 to 20 breaths per minute, and Positive End Expiratory Pressure (PEEP) from 5 to 20 cm of H2O. Due to the current prices of portable ventilators ranging from $5000-$15000, another goal would be to make this design less than $100. We have to make sure that our prototype is low-cost, yet delivers accurate results for the standards of BVM’s.

Manual BVM’s are inconsistent with results due to its manual compression and are not very reliable. The research we have done has helped the team better understand what is required in the final design. In particular, we know that the proposed automated control system with the mechanical compression system would provide the results needed for the patients based on user inputs.

Comments