Capstone I: Progress Blog #3

- John Santos

- Mar 2, 2020

- 4 min read

Updated: Sep 9, 2020

What we've done so far...

Over the work period of last month (February 10th - March 5th) the team has conducted extensive research regarding ventilator standards and practices. The niche of our project was identified and we verified the necessary background knowledge and issues associated with manual and portable ventilation to ensure that the project will solve the specific issues of accuracy and cost. In regards to the accuracy of our project, the group has narrowed down the variables that will be used to measure the performance of the device. The project will mediate the breath frequency and volume of air that is output from the mask by the incorporation of a microcontroller.

To ensure the device operates within medical standards, we have concluded that the I/E ratio is the better method for measuring breath frequency. The I/E ratio is the ratio between the time it takes for inhalation to exhalation, both measured in seconds. Furthermore, we will control the volume output by measuring the volume of air exiting the bag with a spirometer and correlate that with a certain displacement when the bag compresses. From previously found research, these two variables will be compared to values used in the medical field on a per patient basis.

We have a solid understanding of the next stages of the design process and are currently brainstorming the components needed to achieve this goal. Regarding the execution of the project, the team has finalized a list of deliverables, validation plan, a list of tasks with associated due dates, and a few base ideas for a compression system that are hand drawn as shown below in Figures 1 and 2.

Figure 1. This conceptual design uses two separate motors to control two separate clamps that can compress the bag. Using the system of gears and pinions, the motors will rotate in opposite directions to create the compression.

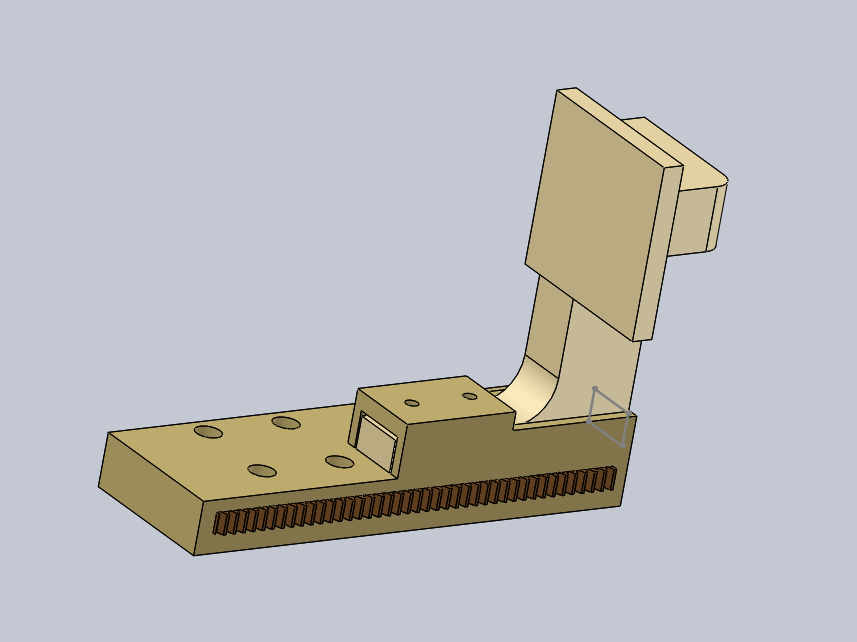

Figure 2. The design in Figure 2 is similar to the one in Figure 1 except it only uses one motor and one pinion. As the motor rotates, the two pushers connected to the two racks will operate in two opposite directions, creating the compression.

Figure 3. Finally, Figure 3 shows a slightly different version of the same mechanism from Figure 2. Instead of having the bag placed on top of the mechanical system, the bag in Figure 3 will be placed underneath the rack and pinion. This design will therefore provide additional protection for the bag during operation.

One of the main concerns of our design is figuring out how we’ll validate and measure some of our set variables. The team is still debating on whether to have PEEP (positive end-expiratory pressure) as a variable due to its complications on measuring results. It will be addressed in our design until there is clarity on its importance or necessity. Since we are designing a medical device, there are standards to follow for safety purposes.

One of the obstacles we are facing is finding a recent and complete PDF file of a standard to follow. Our plan is to look for articles or research papers containing this information showing how they went about using these standards in their area of work. Several incomplete sources were also found with some of the standards but it is undecided on which ones to follow. We will need to identify and choose these standards based on the necessities and goals of our design.

What the Future has in store....

From March 6th to 16th, we plan to complete Milestone 1 by doing research on appropriate electronic components and getting a sense for physical constraints such as mass and volume by looking up the dimensions of existing ventilators. We also plan to begin Milestone 2 by brainstorming possible ideas for the mechanical compression system. These ideas will come in the form of hand drawings, with CAD drawings used for key components. The feasibility of these potential designs will be discussed amongst ourselves, and ideally, an official verdict of which design to use will be made. We also plan to purchase a manual Bag Valve Mask as a model to base our design around. This mask would ideally be one that is commonly used in hospitals.

There are several challenges and potential setbacks we could face over this period. The first potential issue stems from the fact that March 6th to 16th is Spring Break. Motivation to do work on the project would be low, and team members may prefer to spend their time on other obligations such as relaxing or studying for their other courses. Another potential issue will be selecting the electronics due to us not being very experienced in electronics. We would need to figure out what the device needs and which microcontroller and program can provide those needs best for us.

Below is the Gantt Chart that describes the current progress of the team’s project. In the coming weeks, the team will determine the required torque and force to compress the bag, which in turn will help determine the size and constraints of the gear and pinions for the mechanical system. Based on the results of the team’s findings, we will determine the appropriate electronic component. We will also generate several sketches for the mechanical system.

Figure 4. Gantt chart showing our current progress. Milestone 1 is almost completed, and we aim to begin Milestone 2 over the Spring Break.

Comments